Permanent staff : Sylvie Delpech, Céline Cannes, Davide Rodrigues

PhD students : Joelle Costantine, Letissia Hamza, Marc Cabrières

Post-doctoral researchers : Almaza Abi Khalil, Gabriela Duran Klie, Gada El Jamal, Orhun Kahraman

NAAREA engineers : Hugo Sauzet, Kim Le, Charly Carrière

STELLARIA engineers : Amandine Calmet, Thomas Dumaire

Description of the research activities

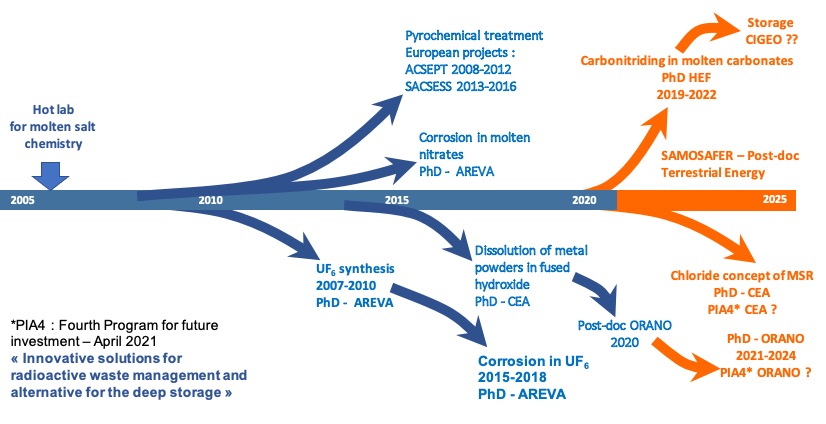

A molten salt chemistry laboratory was set up in Orsay in 2005 to study the concept of a fast-spectrum molten salt reactor (the Molten Salt Fast Reactor, MSFR) developed by the CNRS in the frame of the national program PACEN. Since then, experimental studies on the chemistry and treatment of liquid fuel (composed of a mixture of LiF, ThF4and UF4) have been carried out with national support but also through several European projects and an industrial collaboration with RHODIA (up to 2016), interested in a possible way of upgrading thorium. For two years, a new research path for the concept of molten salt reactor has been emerging, based on the U/Pu nuclear fuel cycle and a molten chloride salt. In this context, within the CHIMENE team, we are working with the CEA on the corrosion reactions of structural materials in such a media.

Molten salts are solvents whose chemical properties are very varied and depend on the nature of the salts entering into their composition. The installation of the laboratory for the study of molten salt reactor chemistry in Orsay and the associated experimental devices made it possible to broaden our field of expertise and to invest in other research themes related to the chemistry of molten salts, such as the pyrochemical treatment of solid fuel (ACSEPT and SACSESS European projects), the chemistry of heat transfer salts based on molten nitrates for sodium fast reactors or concentrated solar power plants (AREVA), the direct production of UF6(g) and its interaction with structural materials (AREVA), the carbonitriding of low carbon steels in molten carbonate media (HEF) or the dissolution of pulverulent metal waste in molten hydroxides (CEA and ORANO).

Highlights (2023)

- Influence de la chimie des sels fondus (potentiel redox, chloroacidité, oxoacidité) sur la réactivité des espèces et matériaux.

- Méthodes de protection des matériaux de structure vis-à-vis de la corrosion dans les sels fondus.

- Synthèse de sels contenant UCl3 ou ThCl4.

- Dissolution de l’uranium dans les hydroxydes fondus.

Collaborations

LPSC Grenoble, CEA Saclay, CEA Marcoule, CEA Cadarache, ORANO, University of Berkeley, SOLVAY, HEF, NAAREA, STELLARIA

PhD thesis in progress

Joelle COSTANTINE, Chimie des sels chlorures fondus pour les concepts de réacteur nucléaire à sels fondus, ORANO funding, Université Paris-Saclay, 2022-2025

Letissia HAMZA, Développement d’un procédé de dissolution des déchets métalliques pulvérulents en milieu hydroxydes fondus, ORANO funding, Université Paris-Saclay, 2022-2025

Marc Cabrières, Etude de produits de fission en milieu sels fondus chlorures, Projet France 2030 ISAC, 02/2024-01-2026.

Post-doctoral researchers

Gabriela Duran Klie, Définition d’une méthode d’extraction du combustible usé par réduction en milieu sels fondus, Projet européen MIMOSA, 01/2023-09/2024.

Almaza Abi Khalil, Etude d’un procédé de préparation de ThCl4 anhydre pour les réacteurs à sels fondus, Projet France 2030 PORTHOS, 10/2023-09/2024.

Guada El Jamal, Etude de produits de fission en milieu sels fondus chlorures, Projet France 2030 ISAC, 02/2024-01-2026.

Orhun Kahraman, Traitement du sel combustible usé pour les réacteurs à sels fondus chlorures, Projet France 2030 MOSARWASTE, 03/2024-02/2026.

Defended PhD thesis

Alexandre CHMAKOFF, Corrosion mechanisms understanding in the environment of future reactors using molten salt fuel and coolant, CEA funding, Université Paris-Saclay, 2023

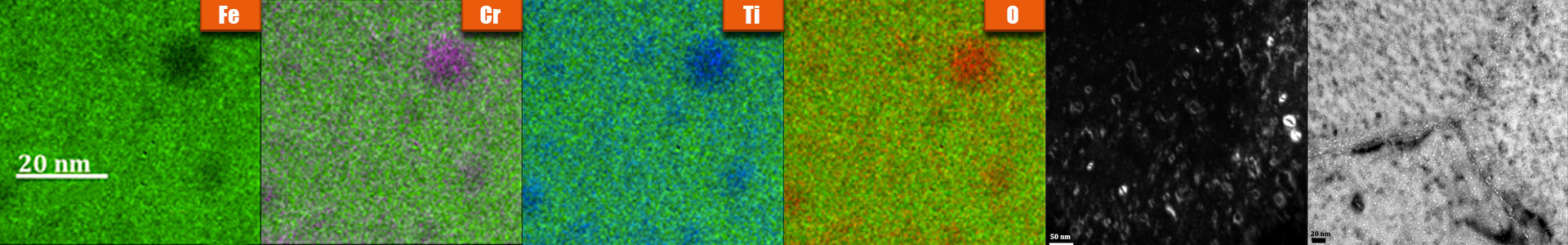

Hugo SAUZET, Study of nitrocarburizing process of steel in molten salts, CIFRE – HEF funding, Université Paris-Saclay, 2022

Mickael ACHOUR, Corrosion mechanism of iron in liquid UF₆ at 80°C, ORANO funding, Université Paris-Saclay, 2018

Gabriela DURAN-KLIE, Study of uranium and iodine behavior in the molten fluorides LiF-ThF₄ at 650 ° C, Venezuela funding, Université Paris-Saclay, 2017

Thi-Kim-Khanh LE, Study of corrosion of steel in molten sodium nitrate at 340°C, AREVA funding, Université Paris-Saclay, 2016

David RODRIGUES, Actinide/lanthanide separation in molten salt media : application to the MSFR fuel reprocessing, CIFRE – RHODIA funding , Université Paris-Saclay, 2015

Marie LUCAS, Electrochemical microscopy in molten salt medium : experience, modeling and application to the study of corrosion, Ecole Doctorale Paris funding, Université Pierre et Marie Curie, 2013

Sébastien JASKIEROWICZ, Fuel reprocessing of the fast molten salt reactor : actinides et lanthanides extraction, CIFRE – RHODIA funding, Université Paris-Saclay, 2012

Last publications

Sylvie Delpech, Charly Carrière, Alexandre Chmakoff, Laure Martinelli, Davide Rodrigues, Céline Cannes, Corrosion mitigation in molten salt environments, Materials 17 (2024) 581

Participation of S. Delpech to the Handbook of Generation IV nuclear reactor, Second edition, Edited by Dr Igor PIORO, Elsevier, 2023.

Gabriela Duran-Klie, Davide Rodrigues, Sylvie Delpech, Electrochemical behavior of iodide ions in molten fluoride salts, Electrochimica Acta, 445 (2023) 142019

Hugo Sauzet, Romaric Collet, Christophe Héau, Christophe Pupier, Davide Rodrigues, Céline Cannes, Sylvie Delpech, Redox properties of the carbonate molten salt Li2CO3 –Na2CO3 -K2CO3, Electrochimica Acta, 405 (2022) 139765

Sarah L’haridon-quaireau, Kimberly Colas, Bénédicte Kapusta, Bénédicte Verhaeghe, Marie Loyer−Prost, Impact of ion and neutron irradiation on the corrosion of the 6061−T6 aluminium alloy., Journal of Nuclear Materials, 553 (2021) 15305

P. Soucek, D. Rodrigues, O. Beneš, S. Delpech , A. Rodrigues, R.J.M. Konings, “Electrochemical measurements of LiF-CaF2 -ThF4 melt and activity coefficient of ThF4 in LiF-CaF2 eutectic melt”, Electrochimica Acta, 381 (2021) 138

Michel Allibert, Elsa Merle, Sylvie Delpech, Delphine Gerardin, Daniel Heuer, Axel Laureau, Simon Moreau, “Preliminary proliferation study of the molten salt fast reactor”, EPJ Nuclear Science and Technology, 6 (2020) 5

Sarah L’Haridon-Quaireau, Mathilde Laot, Kimberly Colas, Bénédicte Kapusta, Sylvie Delpech, Dominique Gosset, Effects of temperature and pH on uniform and pitting corrosion of aluminium alloy 6061-T6 and characterisation of the hydroxide layers, J. Alloys and Compounds, 833 (2020) 155146

Mickaël Achour, Laure Martinelli, Sylvie Chatain, Laurent Jouffret, Marc Dubois, Pierre Bonnet, Ania Selmi, Bertrand Morel and Sylvie Delpech, “Corrosion of iron in liquid uranium hexafluoride”, Corrosion engineering Science and Technology, 52 – 8 (2017) 611